The wood used in the manufacture of percussion instruments varies according to the area of origin; In Latin America, the variety of trees is enormous, in North America the maple is the most sought after and in Europe beech and birch have always been used to build percussions in general. Fortunately, birch has the right characteristics for the cajon, since it offers a very sharp and clear sound. And just like drum kits, plywood is often used to make cajons.

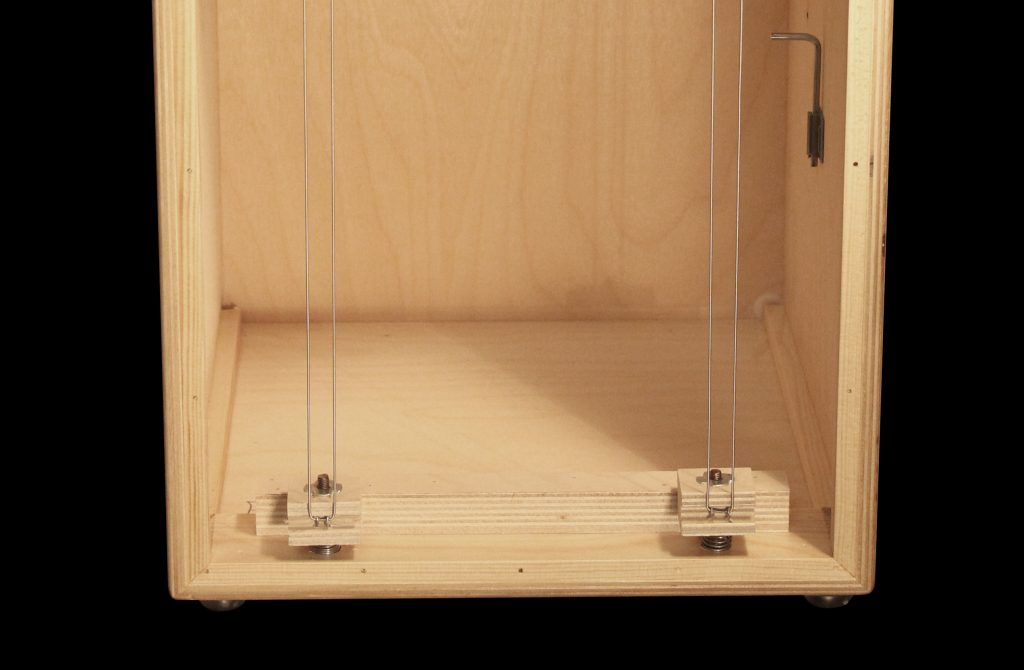

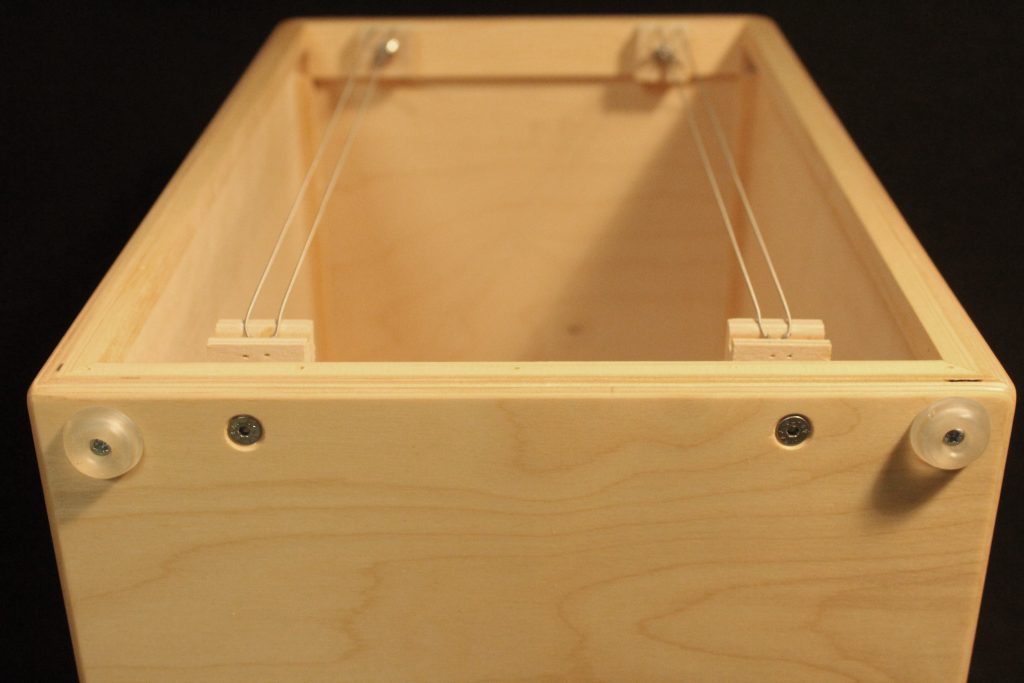

Most of DG cajons are made of birch. The different parts are combined with ultra-resistant vinyl glues, and varnished with a double layer of polyurethane product.