La madera utilizada en la fabricación de instrumentos de percusión varía según la zona de proveniencia; en Latinoamerica, la variedad de árboles es enorme, en Norteamérica el arce es el más cotizado y en Europa haya y abedúl se utilizan desde siempre para construir percusiones en general. Afortunadamente, el abedúl tiene las características adecuadas para el cajón, ya que ofrece un sonido bastante agudo y claro. Y así como para los tambores de batería, el contrachapado se suele utilizar para fabricar cajones.

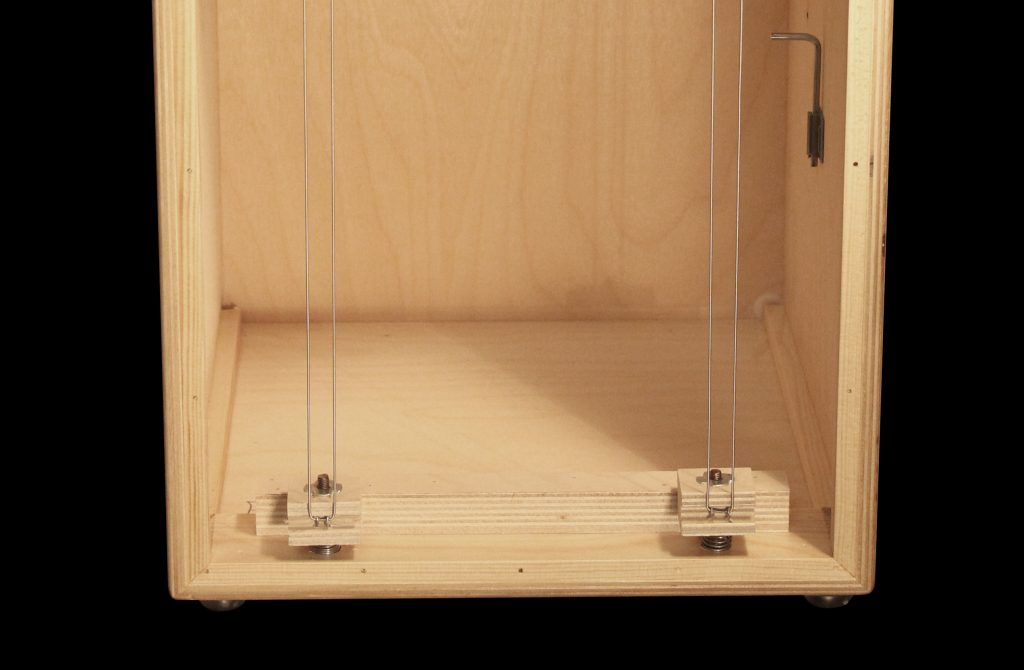

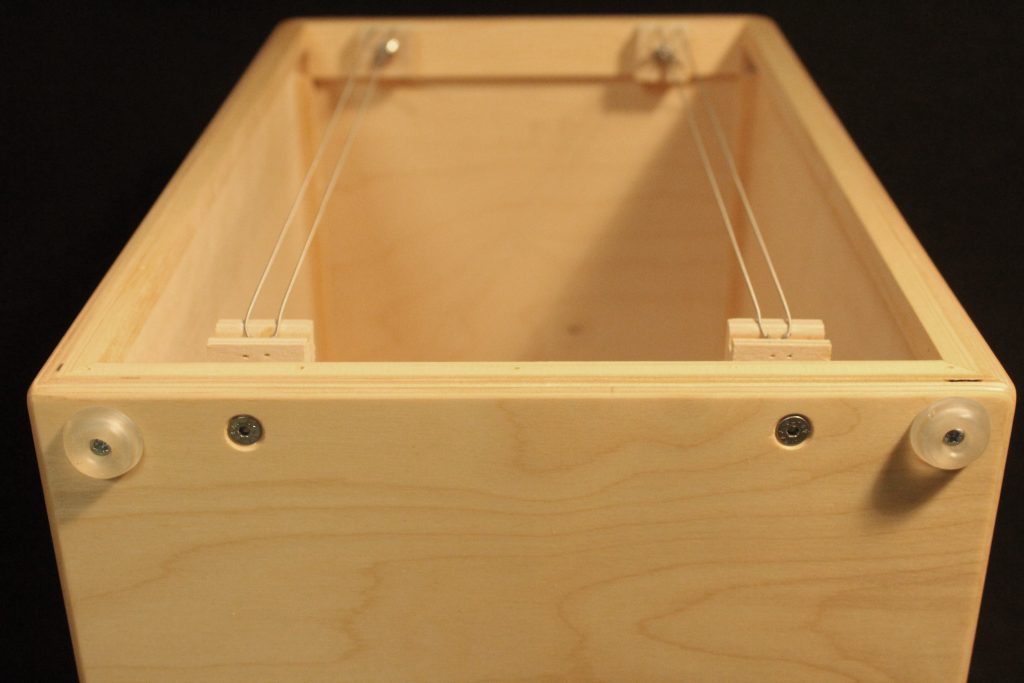

La mayor parte de los cajones DG están hechos de abedúl. Las distintas partes se juntan con colas vinílicas ultra resistentes, y se barnizan con una doble capa de producto poliuretánico.